Produce

Zerella Fresh reinvests in Wyma

South Australia’s Zerella Fresh this month committed to expanding the capacity of their potato washing and grading line. Building on a long and successful relationship, Zerella Fresh has again chosen to reinvest with Wyma Solutions for their post-harvest needs.

Wyma partnerships ready to bear fruit

Wyma Solutions, based in Christchurch, is a globally recognized solution provider for root vegetable packing facilities. Our reputation for innovative, customized and robust post-harvest vegetable processing solutions has been well established for many years, and we have partnerships with several

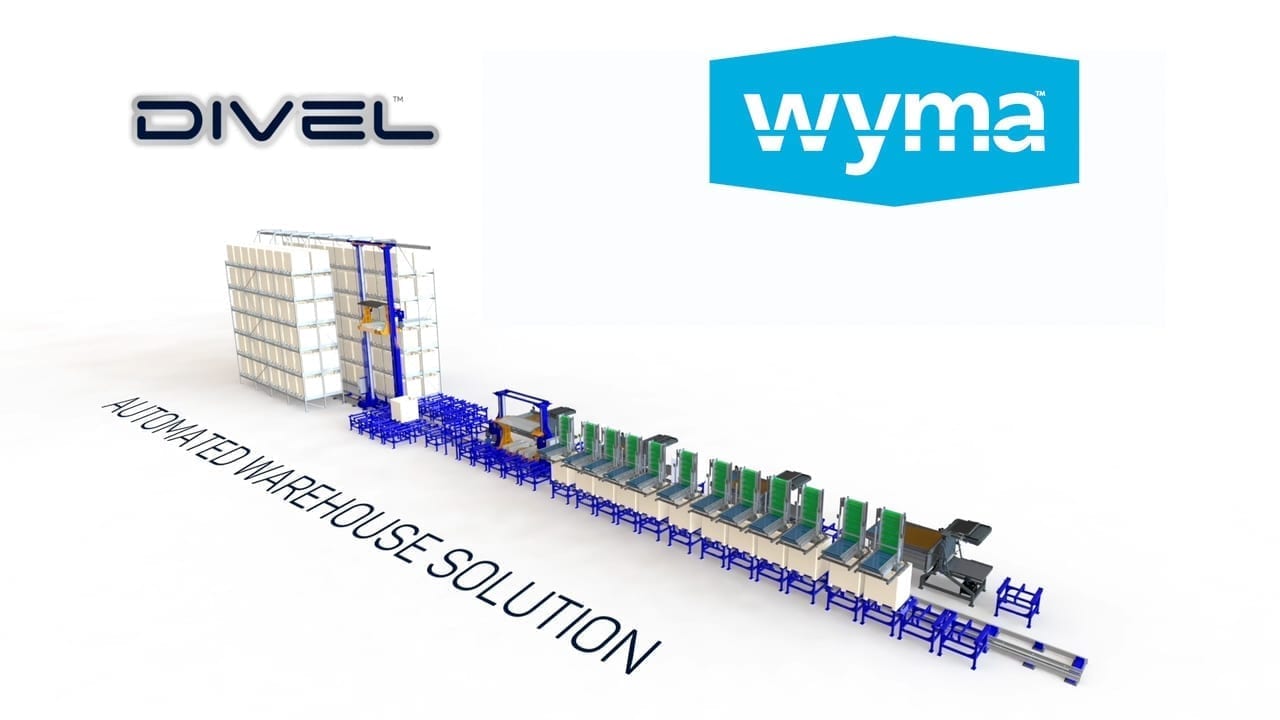

Reduce damage, and increase productivity, shelf life and efficiency, with automated bin warehousing

Wyma has recently added automatic bin warehousing to its portfolio of packing shed products. Automated warehousing systems (ASRS) have significant benefits for fruit and vegetable packers needing short term storage between washing, pre-grading and packing.

Does size matter? (Only if you want to be competitive).

Choosing the right size can have big implications, and not just with chillies!

Continuous innovation at heart of Kalfresh’s success

Kalfresh Vegetables began as a small, family-owned business in Queensland, Australia. Today, it’s a multi-million dollar produce business that has a winning philosophy: “Innovate to keep growing.”

Want to avoid potato bruising and increase profit?

Potato bruising is a serious problem that costs growers hundreds of millions of dollars every year.

Potatoes, a commonly misunderstood nutritional powerhouse

If you knew there was a vegetable which would help to support a large number of health aspects you would make sure it was a staple in your diet, right?

You can have any colour you want as long as it’s orange

How can growers reduce post-harvest losses with carrots?

Wyma’s Vertical Bin and Bag Filler offers automated, gentle produce handling

Over the years, many customers have come to us wanting a bin filler that gently handles their produce; from the first piece to the last.

Potato packing sheds in North America put their handling in Wyma’s hands

Wyma have designed, manufactured and installed a number of russet potato lines over the past 15 months. Packers in Washington, Oregon, Idaho and Minnesota States have turned to Wyma to solve problems associated with increased service and maintenance costs on their handling equipment, and a decrease