Equipment spotlight

Two decades on, Wyma Vege-Polisher™ continues to impress

A discussion you often hear around the Wyma offices is around which elements of our equipment and processes are the most valuable to our customers. The commitment to innovation and continuous improvement is a common answer. Maybe it’s our focus on service and support. Or what about the flexibility

Equipment Spotlight – Electric Bin Tipper

As food safety emerges as one of the most imminent priorities for fruit and vegetable growers, the Wyma team is constantly looking to improve on our designs and deliver the best possible solutions. That spirit of continuous innovation led to the development of the Electric Bin Tipper, a project

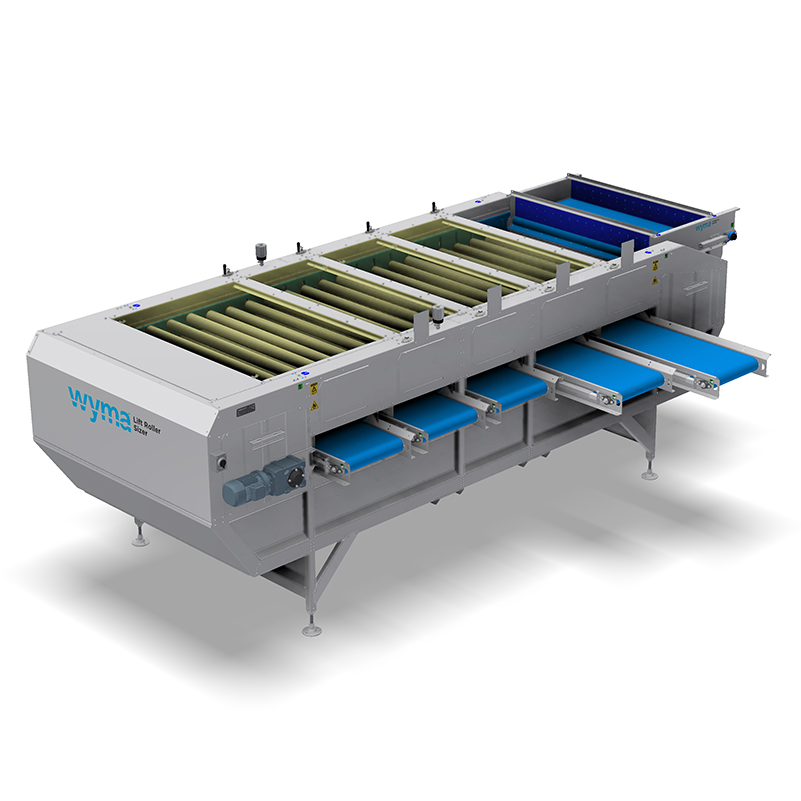

Equipment Spotlight – Lift Roller Sizer

Accurate sizing and handling are central to maintaining the quality and marketability of your produce. For carrots, potatoes and onions, sizing is especially important. With their non-uniform shape and variable textures, sizing root vegetables accurately and cost-effectively can be a challenge.

Hoppers, bunkers, bins and boxes

The post-harvest industry, like many others, is full of jargon and terminology. What one person views as a ‘hopper,’ another may call a ‘feeder,’ ‘tank’ or ‘bunker’! Accurate terms and names matter. They reduce confusion, allow for mutual understanding and pave the way for collaboration and

Choosing the right packaging equipment for your processing line

With so many weighing and packaging options available, it can be difficult to narrow down the right fit for your processing line.

Hard polishing before cutting for crisps with Wyma Vege-Polisher™ system

Potato crisp manufacturing is a competitive industry, one where efficiency is a crucial factor in staying ahead of the competition. Wyma’s Vege-Polisher™ system combines both polishing and peeling technology in a unique package to minimise the impact and wear on downstream potato processing

Stainless steel: The material of choice

At Wyma we recognize the unique benefits of stainless steel. Its immediate appeal to the post-harvest industry is its corrosion resistance and hygienic properties, critical for a sector under increasing pressure for food safety compliance. Stainless steel is the obvious choice for our equipment,

Power consumption matters

At Wyma Solutions, our engineering and installation teams work tirelessly to ensure that our customers get the best from every harvest. This dedication extends beyond produce handling to encompass all aspects of post-harvest operations; from preserving freshness and preventing bruising to labor and

Service bulletin – Web Belt Repair and Replacement

Wyma Web Conveyor belts – both standalone and integrated into equipment such as the Wet Hopper – are designed to allow debris or water to fall through the belt, separating it from produce flow. They’re a great solution for harsh operating conditions, often used at the start of a line when incoming

Get the best from your equipment

Well designed and maintained equipment is critical to ensuring the quality and throughput of any post-harvest line. Wyma’s philosophy is always to design and manufacture equipment that is fit for purpose, robust and that performs season after season.