Home / Latest Posts / Engineer Q&A: Stainless steel or mild steel for post-harvest construction?

Engineer Q&A: Stainless steel or mild steel for post-harvest construction?

We’re often asked about the differences between stainless steel and mild steel, and what the best option is for post-harvest equipment. To answer this, we caught up with Goulwen Robinet, Design Engineer at Wyma.

Q: What are the differences between stainless steel and mild steel?

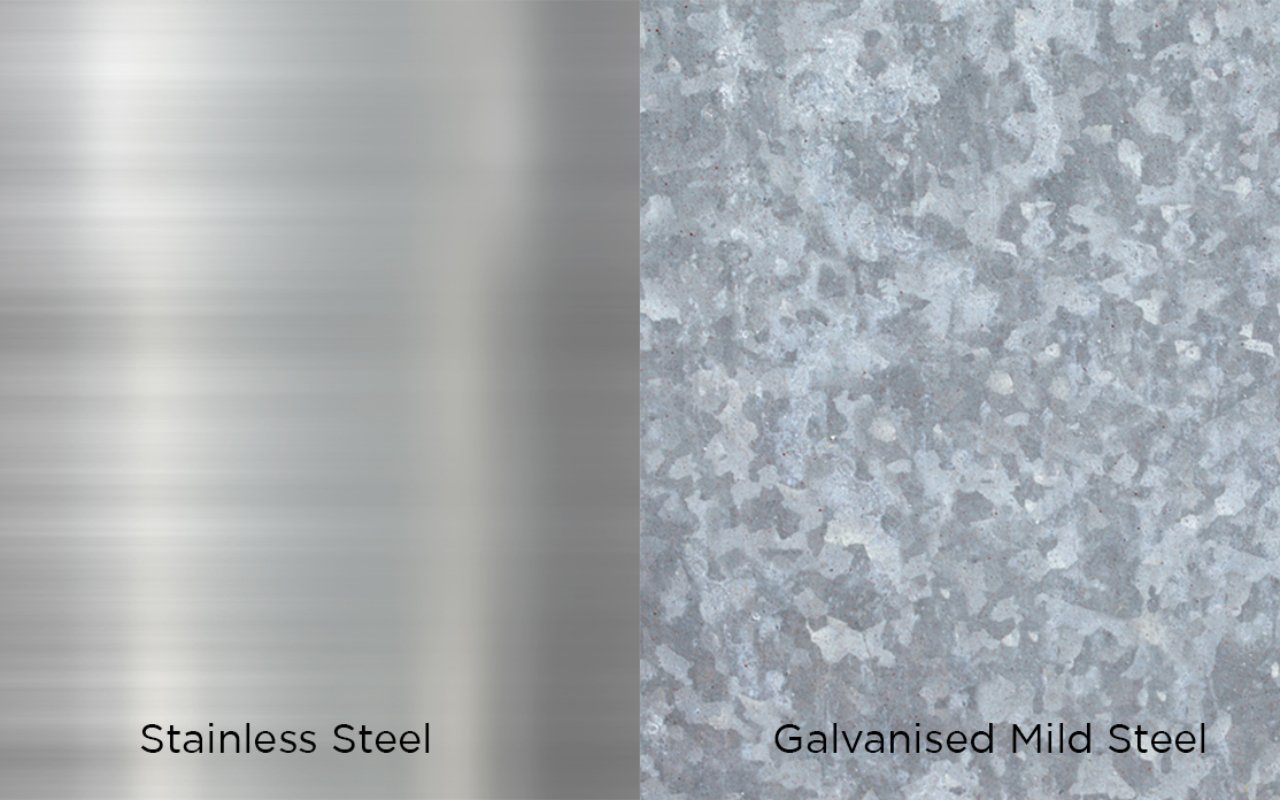

A: Stainless steel and mild steel each have properties that make them unique. They are both iron-based metals yet they react very differently to fabrication and to the environment. Both are made up of carbon and iron, however stainless steel adds a third element – chromium – that provides its rust resistance.

Mild steel is much more malleable than stainless steel, making it easier to work with during fabrication. It can be bent, welded and cut easily, but the lack of chromium means it is not corrosion resistant and will rust over time. Galvanising or painting the steel does offer protection from the elements, but rust still remains a concern – mild steel equipment needs to be cleaned down every day with a chemical solution, adding up to a lot of maintenance over the years.

Stainless steel is a little more difficult to work with so generally requires more experienced fabricators, and as such it carries a higher initial cost than mild steel.

Q: What makes stainless steel resistant to rust?

When mild steel reacts with oxygen and water it builds up a layer of iron oxide, more commonly known as rust. With stainless steel, however, the chromium within reacts with oxygen and produces a layer of rust-resistant metal oxides and hydroxides. This film also acts as a barrier between the surface of the metal and oxygen and water in the environment.

Q: Why would some post-harvest equipment manufacturers prefer to use mild steel?

There are benefits to using mild steel. Galvanising does prevent rusting and other elemental damage. It’s generally easier to work with so some companies may find greater efficiency from their labour. More specialised machinery may not be needed in the manufacturing process. Mild steel is also cheaper to purchase than stainless, which is beneficial for manufacturers that don’t have the allowance in their margins to accommodate the higher cost of supplies.

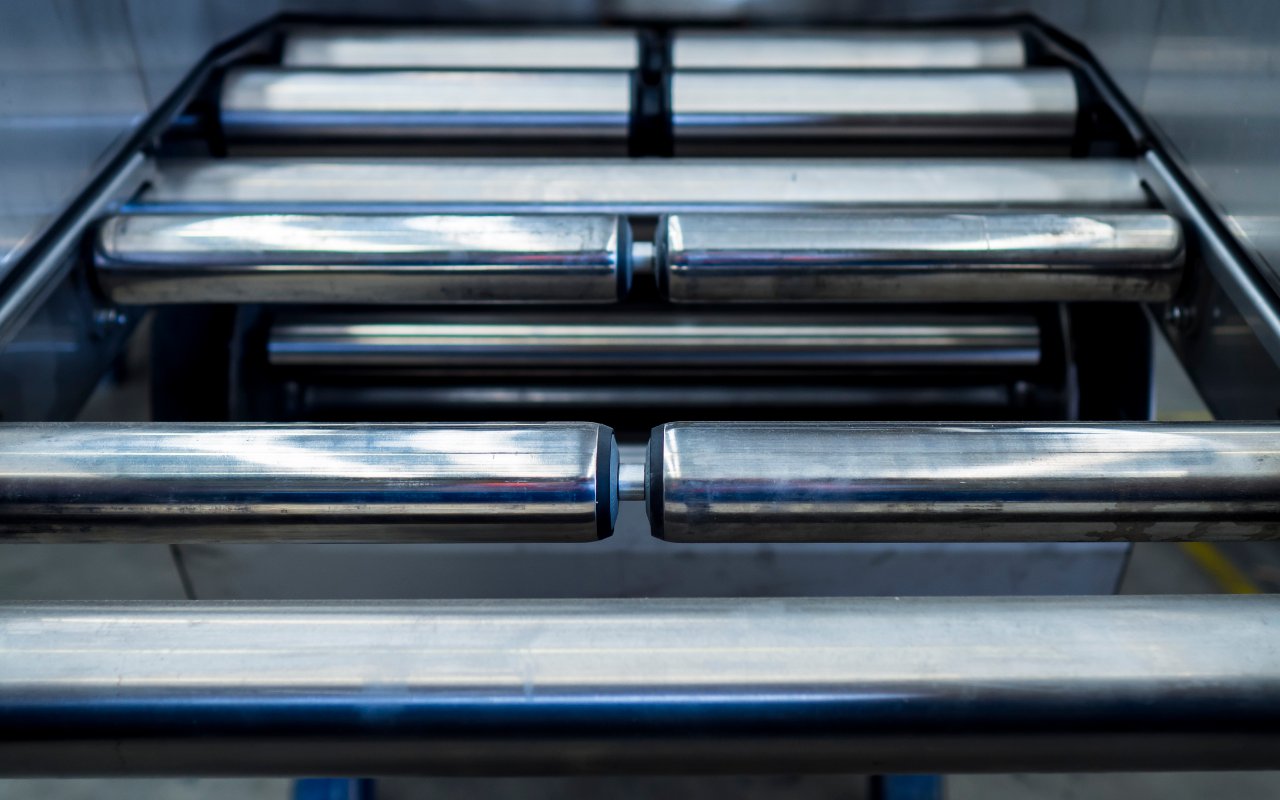

Q: Why does Wyma use stainless steel over mild steel?

In the past Wyma has used a lot of mild steel, but we have transitioned in the past few years to using mostly stainless steel for our equipment. The benefits that stainless provides for post-harvest equipment (improved hygiene, greater elemental resistance, etc.) add up to a better product, and the higher initial cost is offset by the ease of maintenance and longer equipment lifespan. With the majority of our customers being in the food industry, hygiene standards are their top priority.

The price of stainless steel may increase the price of the end product, but that extra investment always results in higher-quality equipment and in the long run a better return on a customer’s investment.

Innovative vegetable trimmer installation nearing completion

Frederick Hiam Foods has invested in six Roto-Cut Trimming systems and six Produce Singulators which make up the core of their new high efficiency automated parsnip processing line.

Sustainability in the pack-house

The world’s food production industry sits at a difficult crossroads. By 2050, the global population will likely increase by 35%, and food production will need to double in that timeframe. However, as our climate changes and resources become scarcer,

People of Wyma: Matthias Kerkmann

As Wyma has grown and evolved, the projects we work on have become increasingly more complex. Developing processing line solutions capable of dozens of tonnes per hour requires a high level of innovation, collaboration and commitment.

-

Fortifi launches Global Food Processing Solutions groupApril 2, 2024

Fortifi launches Global Food Processing Solutions groupApril 2, 2024 -

-

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023