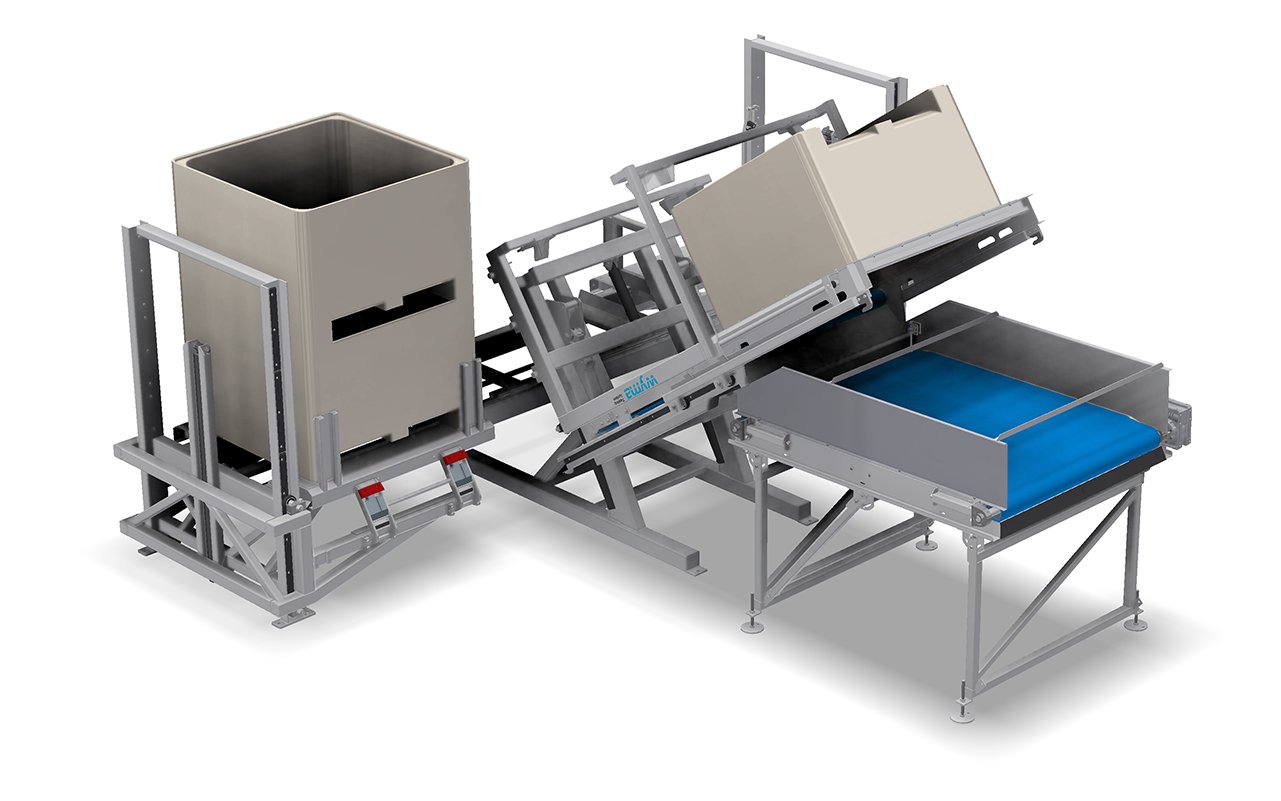

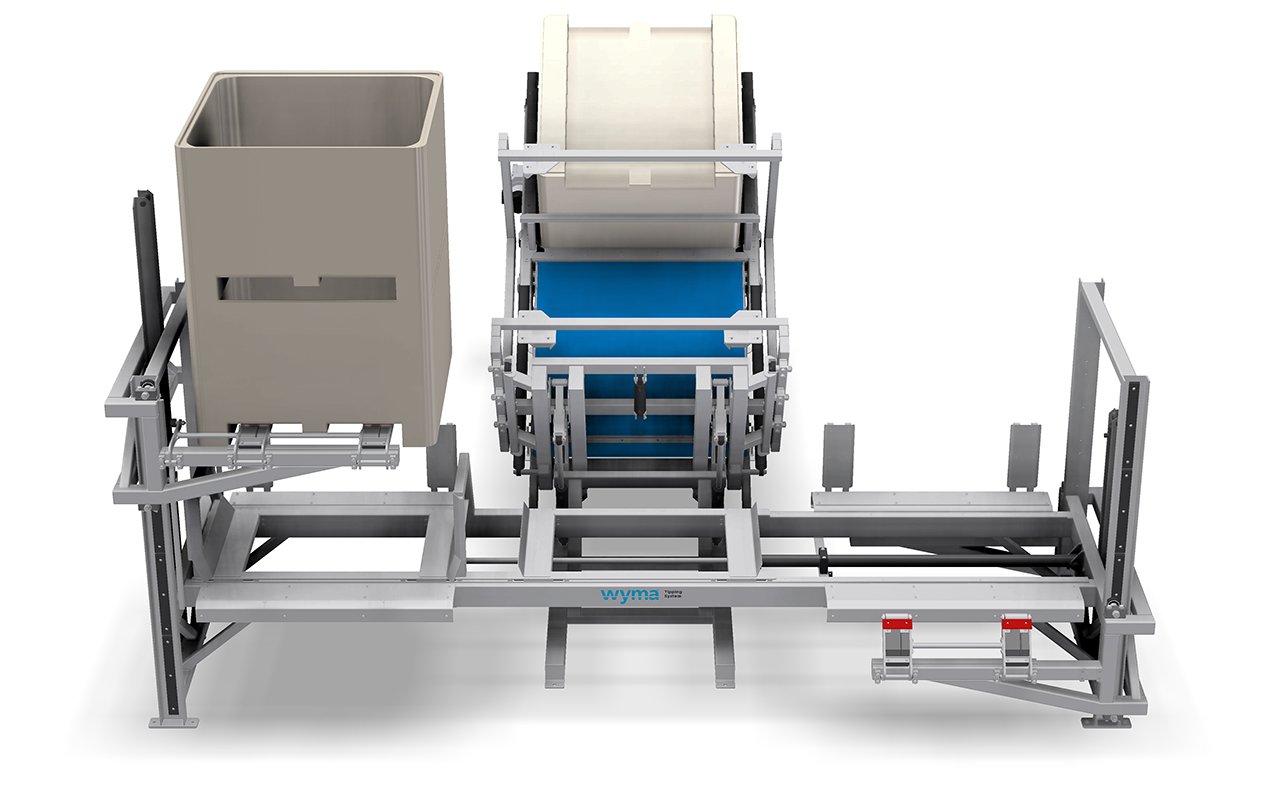

Wyma’s Tip & Stack System receives, tips and re-stacks bins. It can manage three bins simultaneously, reducing the required labour at the start of your line. As with all Wyma tipping solutions, the tipping process is very gentle with minimal produce drop.

Features

- A forklift stacks full bins in the loading zone.

- The bottom bin moves to the tipping zone in the centre.The bin rotates and produce is gently tipped out. You can pause the tipping motion at any time to control produce tip rate.

- The empty bin rotates back to the centre and moves to the other side for unloading.

- The bottom bin from the loading zone moves to the centre for tipping.

- This process repeats until all bins are empty.