Wyma Hydro-Coolers quickly reduce the core temperature of fresh produce, extending shelf-life while preserving flavour and appearance.

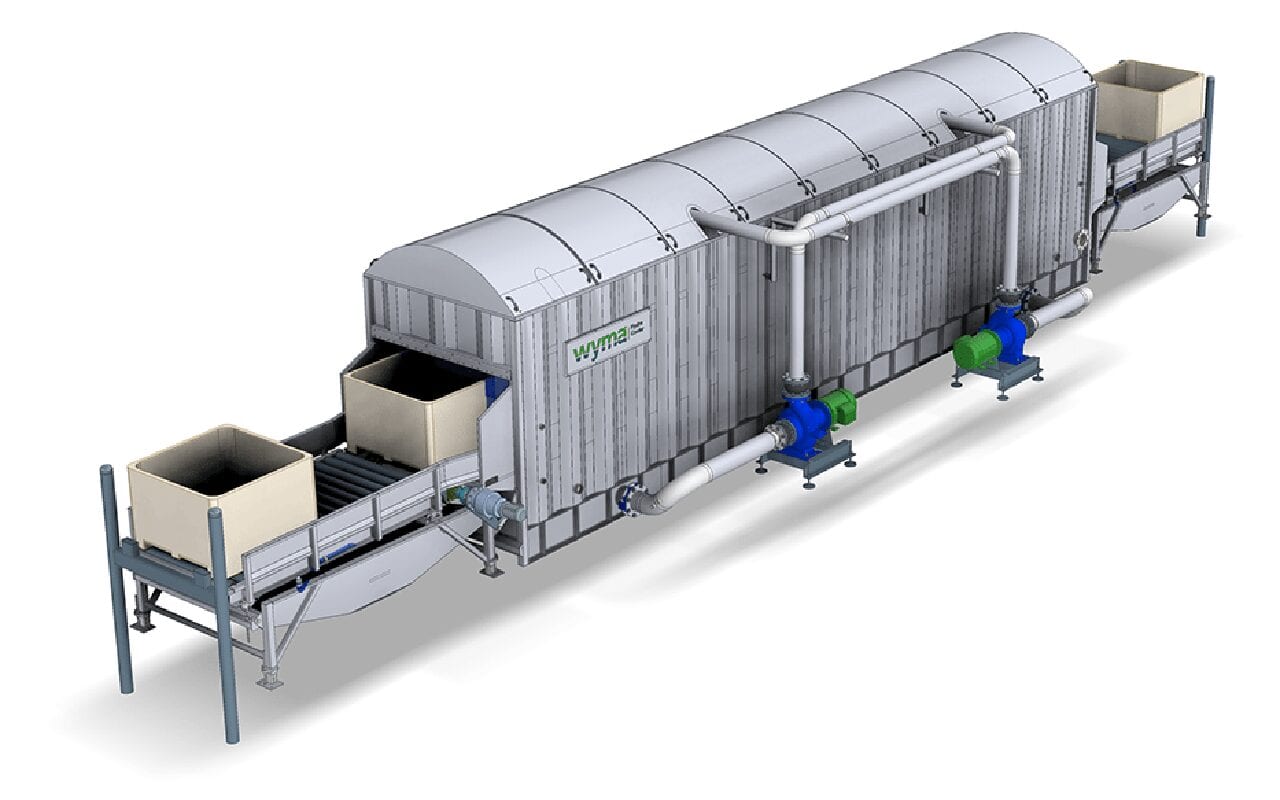

Water is sprayed over a heat exchanger which is cooled to several degrees below freezing by refrigerant. As the water passes over the heat exchanger, the water cools to a user-set temperature. Cooled water then floods down onto produce. Water is collected in a tank at the base of the Hydro-Cooler for recycling.

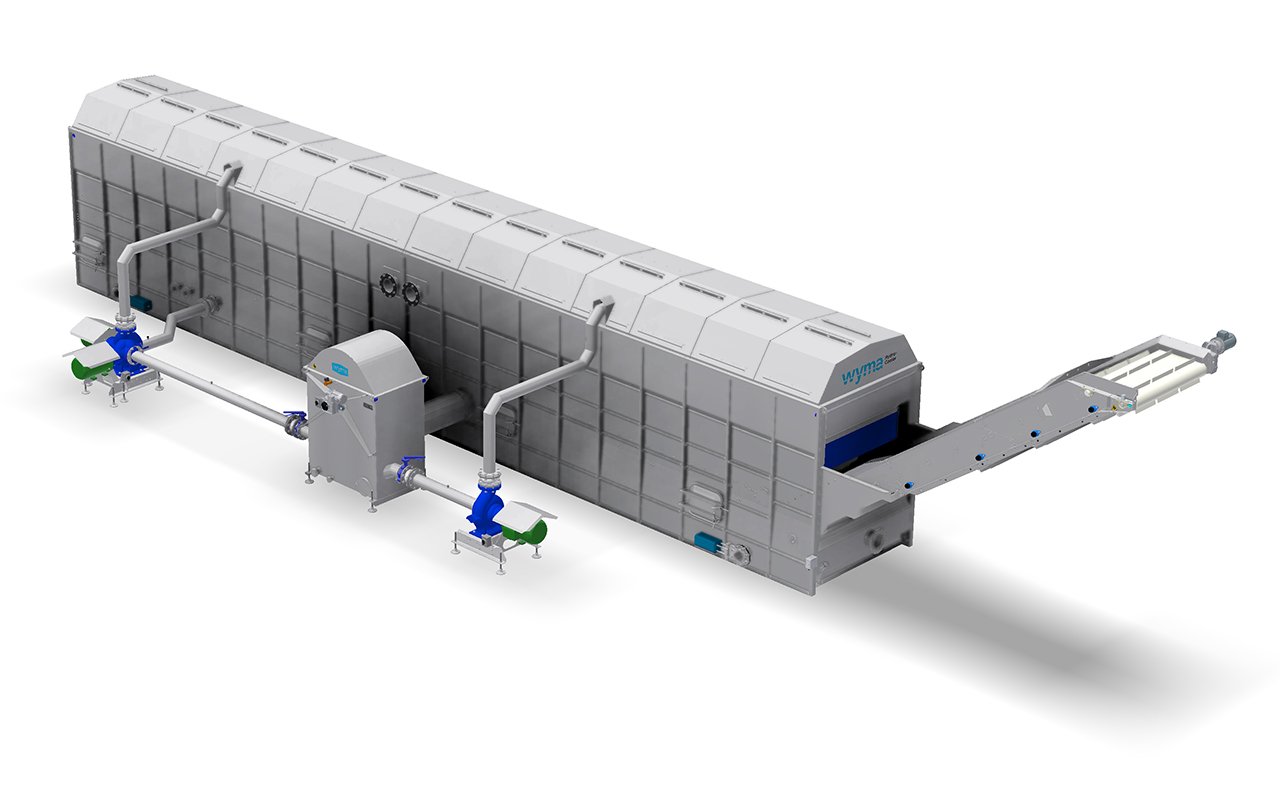

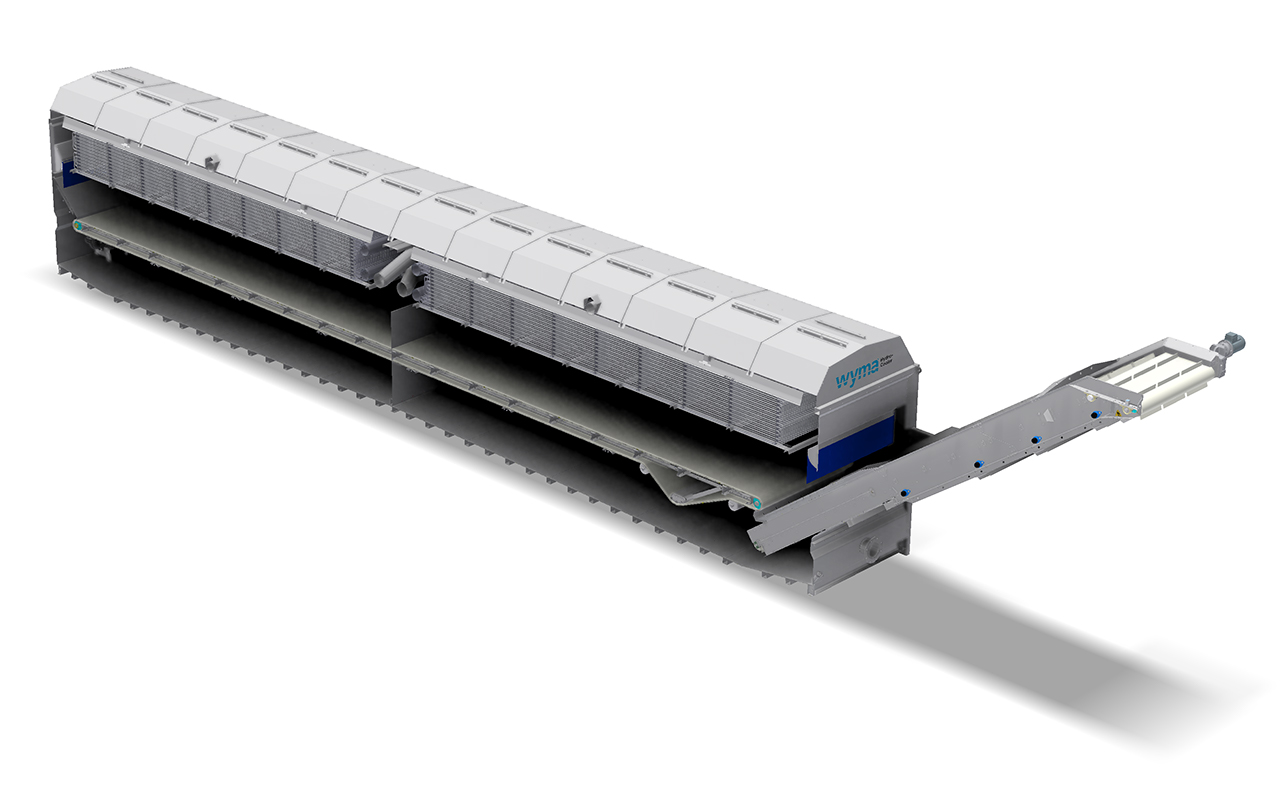

We have two types of Hydro-Cooler that can handle loose produce:

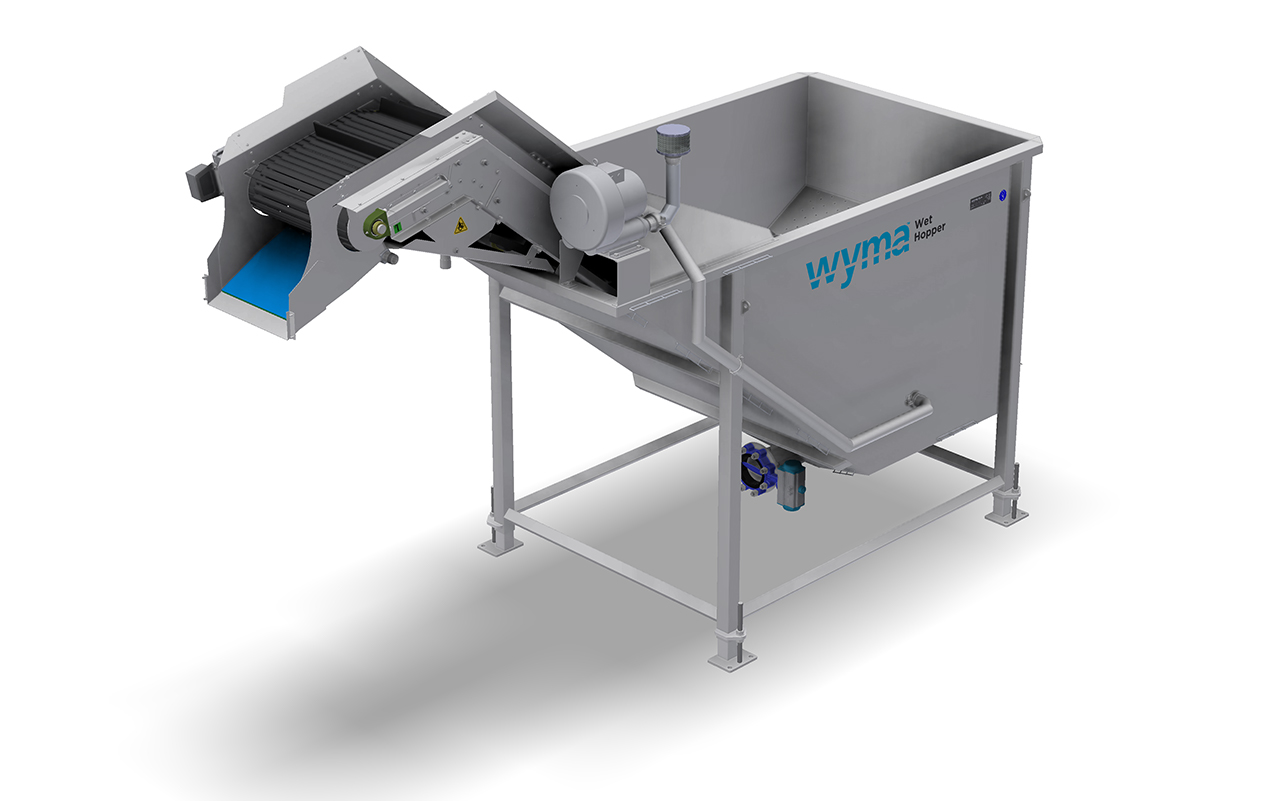

Hydro-Cooler for loose produce: Produce travels by conveyor through the Hydro-Cooler. Produce can be partially or fully submerged in water. An outfeed elevator gently carries produce to the next stage in your line. Suitable for carrots, potatoes, parsnips, etc.

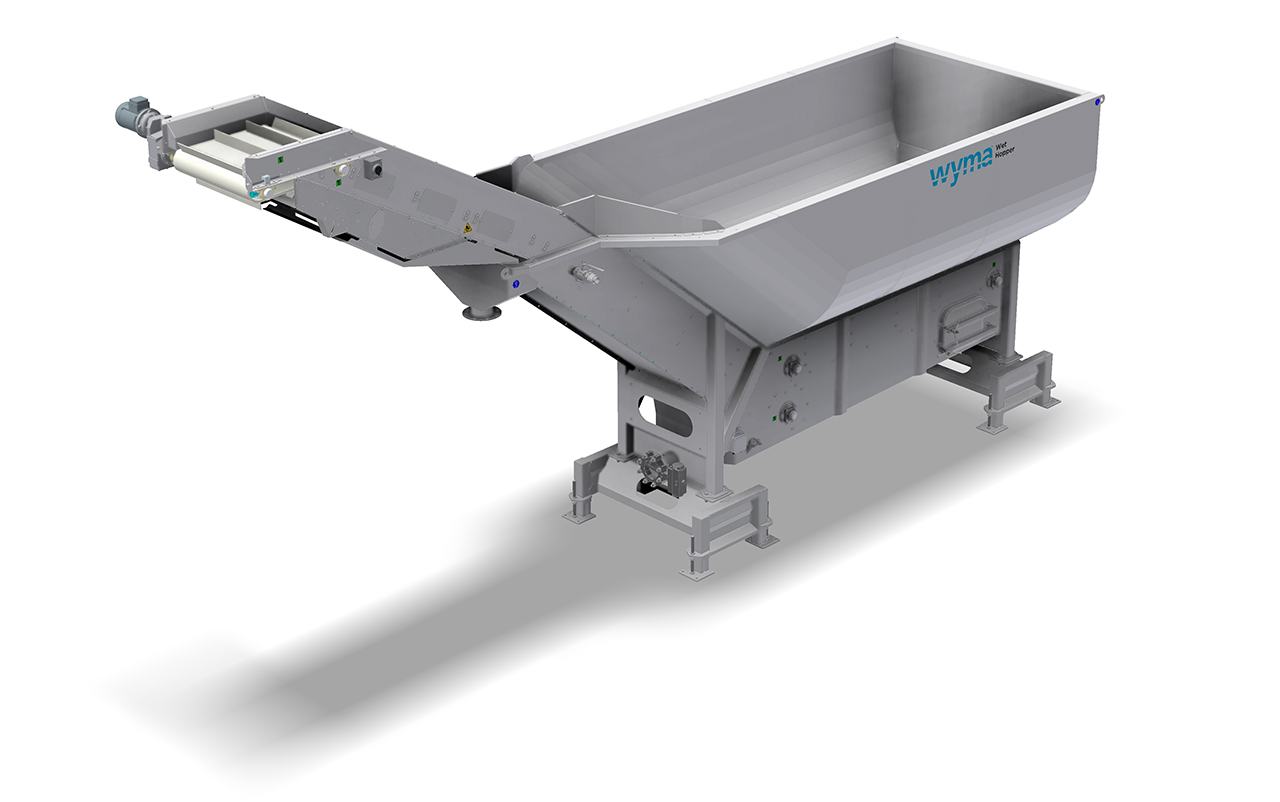

Flow-through Hydro-Cooler for small plastic bins or loose produce: Bins or loose produce travel by conveyor through the Hydro-Cooler. Produce is sprayed with cooled water. This model is commonly used for broccoli, asparagus, cherries, radishes and beetroot (beet).

At Wyma, we have an in-depth understanding of the post-harvest handling and cooling processes. Dwell time, equipment and refrigeration specifications are tailored to meet your needs.

Features

- Quickly reduces core temperature of produce which extends shelf-life and preserves flavor and appearance.

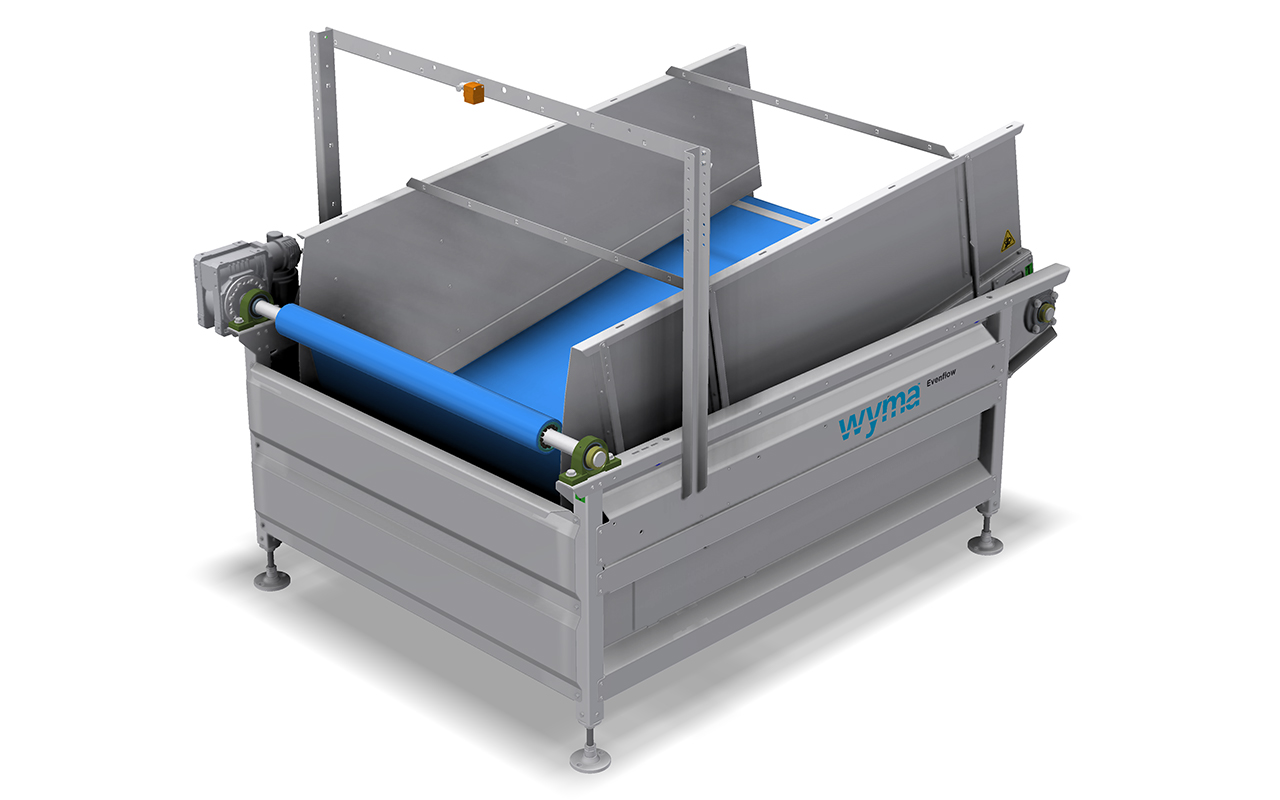

- Produce immersion* improves heat transfer efficiency. A sensor is available to detect water level.

- Variable speed controlled conveyor allows you to control cooling time.

- Stainless steel tank – strong and cleanable.

- Rotary Filter Unit* Provides continuous water filtration to prevent blockages.

- Gooseneck elevator* gently delivers produce to next stage. Extensions available*.

- Drain valves (two) allow the tank to be drained of water. Automatic valves available*.

- Access hatches* for full access for maintenance and cleaning.

- The water spray system cools produce and maintains optimum temperature.

- Integrated coils mean no need for an external heat exchanger.

- The modular belt on the conveyor allows water to fall through to the base of the tank for recycling. Cleanable and serviceable.

- The integrated tank allows semi-immersed cooling.

- Equipment automation with touch – screen smart, easy equipment control.

- Variable speed controlled elevator and pump which allows full equipment control.

- Gravity-aided belt tensioning reduces belt wear.

* Optional