Home / Latest Posts / Power consumption matters

Power consumption matters

At Wyma Solutions, our engineering and installation teams work tirelessly to ensure that our customers get the best from every harvest. This dedication extends beyond produce handling to encompass all aspects of post-harvest operations; from preserving freshness and preventing bruising to labor and cost-reduction features.

Recently Wyma was approached to evaluate a customer’s intake system provided by a competitor. The system comprised a large wet hopper, destoner and an intake elevator. Not satisfied with this systems’ performance, reliability or ease-of-use, the customer asked Wyma to develop an alternative solution.

Our brief was simple: to improve cleaning efficacy and maintain a minimum throughput to match the existing equipment. By working closely with the customer to understand the unique environment, conditions and produce handling requirements, the Wyma design team put together a solution that was scaled and appropriately configured to meet each requirement.

The net result exceeded the customer’s expectations, offering a simple robust solution that was fit for purpose. It resulted in a significant reduction in operating costs due to lower maintenance requirements and dramatically reduced power consumption.

At Wyma we recognize that power consumption is a major cost for all of our customers. Our design team focuses heavily on reducing consumption, so that we can deliver not just the best solution but also tangible benefits to our customers’ bottom line.

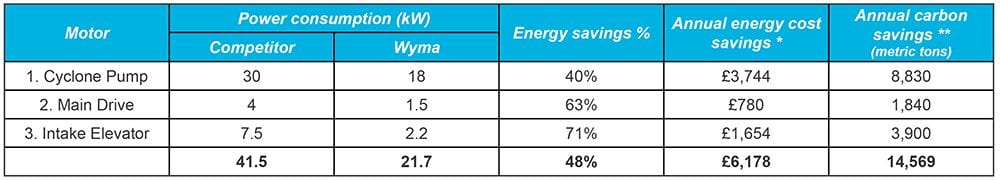

In this specific case, the competitor’s equipment consumed almost twice the power of the equivalent Wyma system. The resulting annual energy cost of the competitor’s machine was £6,134 (US$7,702/€6,846) greater than that of the alternative Wyma solutions (see below).

Equipment type: Wet Hopper

Motors: x3

* Energy cost saving based on rate of 12p/kWh and a 50-hour week

** Carbon reduction based on UK average of 283g of CO2 p/kWh and a 50-hour week

How power-hungry is your line?

Our decades of post-harvest design experience enable us to ensure that each line and machine is optimized, eliminating waste while maintaining the quality and robustness we are known for.

Is your line designed to minimize power consumption while maintaining produce quality and throughput? Contact the Wyma team today and discuss your post-harvest line requirements and power reduction needs.

Innovative vegetable trimmer installation nearing completion

Frederick Hiam Foods has invested in six Roto-Cut Trimming systems and six Produce Singulators which make up the core of their new high efficiency automated parsnip processing line.

Sustainability in the pack-house

The world’s food production industry sits at a difficult crossroads. By 2050, the global population will likely increase by 35%, and food production will need to double in that timeframe. However, as our climate changes and resources become scarcer,

Two decades on, Wyma Vege-Polisher™ continues to impress

A discussion you often hear around the Wyma offices is around which elements of our equipment and processes are the most valuable to our customers. The commitment to innovation and continuous improvement is a common answer. Maybe it’s our focus on

-

Fortifi launches Global Food Processing Solutions groupApril 2, 2024

Fortifi launches Global Food Processing Solutions groupApril 2, 2024 -

-

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023