Home / Latest Posts / Hoppers, bunkers, bins and boxes

Hoppers, bunkers, bins and boxes

The post-harvest industry, like many others, is full of jargon and terminology. What one person views as a ‘hopper,’ another may call a ‘feeder,’ ‘tank’ or ‘bunker’!

Accurate terms and names matter. They reduce confusion, allow for mutual understanding and pave the way for collaboration and further problem-solving. With over 50 years’ experience in producing solutions for the post-harvest sector, Wyma has helped shape some of this terminology.

We’ve put together the below reference guide to Wyma’s definition of hoppers, bunkers, bins and boxes.

Hoppers

These are most often defined as a container for loose bulk material. In other sectors – such as for grain and seed – these usually have tapered sides and the ability to discharge contents from the bottom, but this is not how our sector typically defines them. In our space, hoppers are viewed in two ways: either as a receiving container or for buffer storage. Each function can be performed either wet or dry, and they are emptied via an elevator or conveyor.

|

Dry Hoppers |

|

|

|

For receiving and flow control (others may refer to this style as a bulk feeder, infeed hopper, dirty or receiving hopper). Wyma’s Creep Feed Hopper is a dry hopper. It receives produce with a high level of dirt and clods (from storage of from the field). It allows for fast unloading and change over time without starving your line of produce. |

|

|

For buffer storage (others may refer to this style as a clean or small-volume hopper). Wyma’s Evenflow Hopper is a combination conveyor and hopper. It evenly supplies produce to the next piece of equipment in your line (in a continuous process). It converts an irregular infeed supply to a constant outfeed flow. It can also provide buffer storage. |

|

Wet Hoppers |

|

|

|

For receiving and pre-soaking (others may refer to this style as a soak tank or pre-soak tank). Wyma’s Wet Hopper provides a gentle, pre-washing system to receive produce into washing and packing lines. Our system is comprised of hopper storage, a floor conveyor and discharge elevator, and can also include optional add-ons and/or customized modules for a tailored solution. |

|

|

For buffer storage. Our Clean Wet Hopper receives and stores produce in water prior to packaging, eliminating the need for boxes/bins. Flumes or conveyors gently carry produce to the bunker. Modular conveyor in the base of the bunker move produce towards the outfeed elevator. Speed controlled outfeed elevators carry produce to the next stage in your line. |

Bunkers

These are commonly regarded as a larger container or compartment for longer-term (not buffer) storage, however naming conventions do vary. Bunkers are traditionally dry, however chilled wet bunkers are becoming more common.

|

Dry Bunkers |

|

|

|

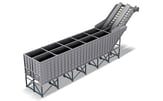

For dry storage (others may refer to this style as a storage bin, bulk bin or storage hopper). Wyma’s Dry Bunker receives and stores produce for automatic, controlled delivery to your processing line. Each Bunker can hold up to 50t of produce with small amounts of dirt and clods. |

|

Wet Bunkers |

|

|

For chilled wet storage (others may refer to this style as a chilled bunker). Wyma’s Chilled Wet Bunker stores chilled produce for automatic, controlled delivery to your processing line. |

Bins and Boxes

Wyma uses the term ‘bin’ for our Bin Tippers, standard terminology in the UK, Australia and New Zealand to describe small forklift-ready produce containers. In North America, bins more often refer to larger containers, such as Bunkers (i.e. bulk bins). In North America and parts of Europe, box or tote is often found as the term used in place of bin.

|

Wyma Bin Tippers

|

Wyma Bin Fillers

|

Innovative vegetable trimmer installation nearing completion

Frederick Hiam Foods has invested in six Roto-Cut Trimming systems and six Produce Singulators which make up the core of their new high efficiency automated parsnip processing line.

Sustainability in the pack-house

The world’s food production industry sits at a difficult crossroads. By 2050, the global population will likely increase by 35%, and food production will need to double in that timeframe. However, as our climate changes and resources become scarcer,

Two decades on, Wyma Vege-Polisher™ continues to impress

A discussion you often hear around the Wyma offices is around which elements of our equipment and processes are the most valuable to our customers. The commitment to innovation and continuous improvement is a common answer. Maybe it’s our focus on

-

Fortifi launches Global Food Processing Solutions groupApril 2, 2024

Fortifi launches Global Food Processing Solutions groupApril 2, 2024 -

-

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023