Home / Latest Posts / Equipment Spotlight – Electric Bin Tipper

Equipment Spotlight – Electric Bin Tipper

As food safety emerges as one of the most imminent priorities for fruit and vegetable growers, the Wyma team is constantly looking to improve on our designs and deliver the best possible solutions. That spirit of continuous innovation led to the development of the Electric Bin Tipper, a project spearheaded by engineer and product manager Matthias Kerkmann.

By reducing the risk of contaminants such as hydraulic oil finding their way into the processing line, the Electric Bin Tipper is a perfect choice for growers and pack-houses. Specifically designed to seamlessly integrate into new or existing processing lines, the Wyma Electric Bin Tipper can feed into a wide array of other equipment including the Wyma Evenflow Hopper which can operate as a conventional conveyor or as a small hopper.

In addition to the increased focus on food safety, the Electric Bin Tipper was developed to improve cost-effectiveness, with lower installation and running costs firmly targeted. Built with smart integrated inverter technology and position control, the tipper requires fewer sensors during operation which reduces wiring complexity and, in turn, installation costs. Similarly, internal testing at Wyma found power consumption during a three-minute cycle dropped 50% when compared with the average hydraulic tipper. This massive saving is complemented by a reduction in wear parts, cutting down ongoing costs required for maintenance.

These great benefits are baked into the Electric Bin Tipper, alongside the flexibility Wyma’s product range is known for. A range of lid options are available to suit an array of produce types and scales of operation:

- Fixed lid with a partial door (standard)

- Soft-tip lid (for gentle handling and controlled discharge)

- Super-tip lid (ideal for tipping directly into a Wet Hopper)

The Electric Bin Tipper comes in a standard configuration to suit the most common size of bins/boxes, but can be customised to accommodate whatever bin size and shape you require.

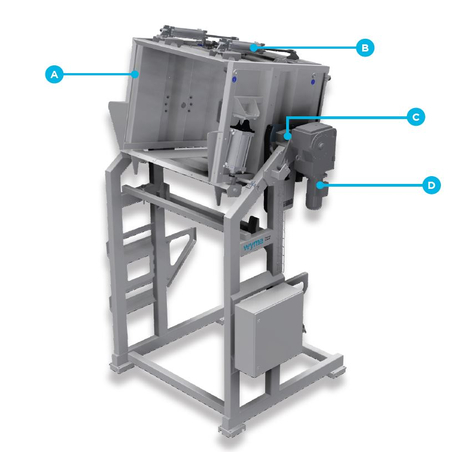

| A Bin cradle to suit your site | Design can be adapted to match your bin sizes |

| B Partial lid option | Can be combined with a Wyma Evenflow Hopper |

| C Central pivot point | Compact design, using less energy to tip |

| D Electric drive | Uses less power and no risk of oil leakage on to produce |

| Soft-tip lid option* | Can provide controlled produce delivery to the start of a line |

| No lid option (fastest tipping)* | Can be combined with a Wet Hopper |

| Double tip action | Makes sure no produce is left behind |

| Programmable velocity profile | Fastest possible cycle time while managing gentle handling requirements |

| Compact, rugged design | Built strong to last, and with minimum footprint |

| Minimal wear parts | Cheaper and easier to maintain |

| Bin cradle inserts* | Can accommodate a second, shorter bin |

For further information on tipping, or post-harvest solutions in general, please contact your Wyma sales representative.

Two decades on, Wyma Vege-Polisher™ continues to impress

A discussion you often hear around the Wyma offices is around which elements of our equipment and processes are the most valuable to our customers. The commitment to innovation and continuous improvement is a common answer. Maybe it’s our focus on

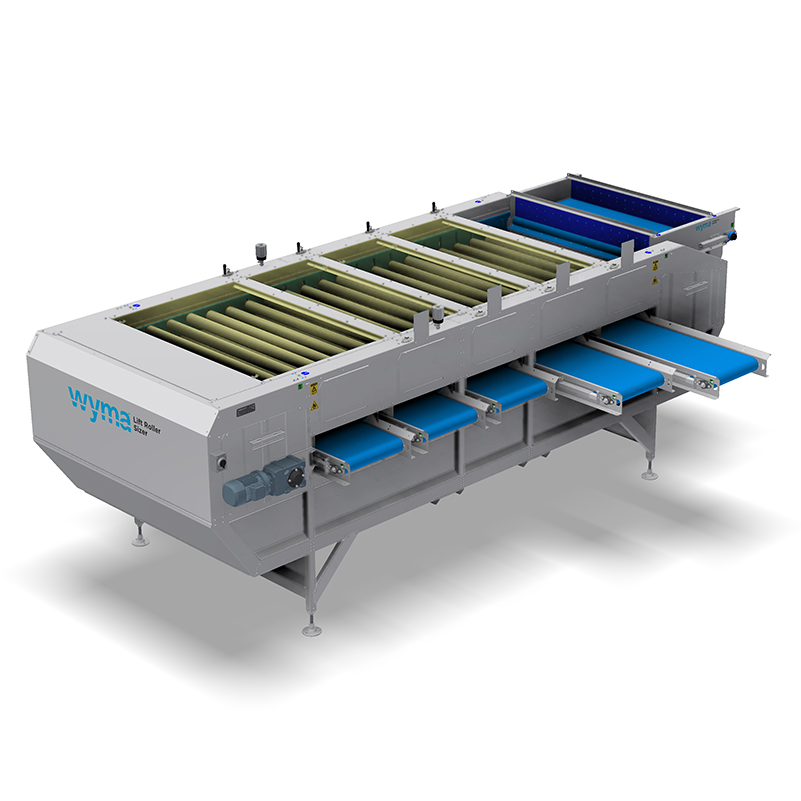

Equipment Spotlight – Lift Roller Sizer

Accurate sizing and handling are central to maintaining the quality and marketability of your produce. For carrots, potatoes and onions, sizing is especially important. With their non-uniform shape and variable textures, sizing root vegetables

Hoppers, bunkers, bins and boxes

The post-harvest industry, like many others, is full of jargon and terminology. What one person views as a ‘hopper,’ another may call a ‘feeder,’ ‘tank’ or ‘bunker’! Accurate terms and names matter. They reduce confusion, allow for mutual

-

Fortifi launches Global Food Processing Solutions groupApril 2, 2024

Fortifi launches Global Food Processing Solutions groupApril 2, 2024 -

-

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023

Revolutionizing Agriculture: Optical Roto-Cut Nominated for FLIADecember 13, 2023